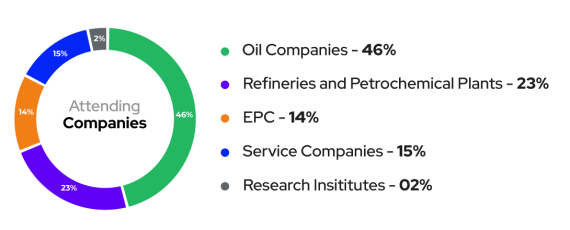

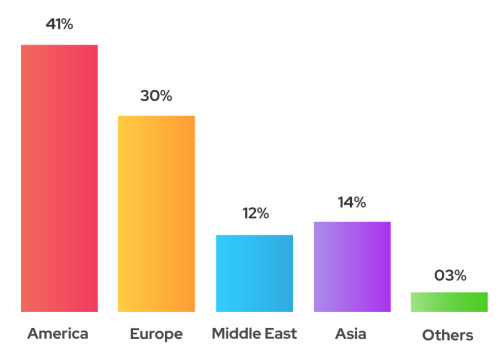

About DTWIN2024

Leverage Digital Twin Technology to boost Profitability and Strategies to Maximize Efficiencies in Oil & Gas Operations

Oil & Gas Digital Twin Conference and Exhibition 2024 create Opportunities to boost Profitability and Strategies to Maximize Efficiencies in Oil and Gas Production.

The Oil & Gas Digital Twin Conference and and Exhibition 2024 is a dynamic gathering where industry professionals and technology innovators converge to accelerate a comprehensive digital transformation in the Oil & Gas sector. This exclusive virtual event explores the digital twin ecosystem, addressing sustainability, operational impact with Digital Twin and Generative AI, upstream sector digital integration, cybersecurity risks, efficiency in Asset Performance Management, and the pivotal role of Digital Twin in achieving a Net Zero Future.

The Oil & Gas Digital Twin Conference and and Exhibition 2024 is a dynamic gathering where industry professionals and technology innovators converge to accelerate a comprehensive digital transformation in the Oil & Gas sector. This exclusive virtual event explores the digital twin ecosystem, addressing sustainability, operational impact with Digital Twin and Generative AI, upstream sector digital integration, cybersecurity risks, efficiency in Asset Performance Management, and the pivotal role of Digital Twin in achieving a Net Zero Future.